Custom Size & Style

Free Shipping

Quick Turnaround Time

No Minimum Order Required

No Die & Plate Charges

Free Graphic Designing

UV Coating

This is a liquid layer that we dry with special lights to give your packaging a very shiny finish.

Aqueous Coating

This is a fast drying water based layer that protects your boxes from fingerprints and scratches during the shipping.

Lamination

We apply a thin plastic film over the paper to make your boxes strong and keep them from ever tearing.

Soft Touch Lamination

This special film makes your box feel as soft as silk and gives your brand a very high-end feel.

Spot Gloss UV

This shiny coating is put only on certain parts of the page to make specific pictures or words pop.

Varnish

A clear ink used to protect the page or add a light shine, though it can yellow over time.

Anti-Scratch Lamination

A tough plastic shield that prevents ugly scuffs and marks from ruining your product when people touch it.

Silk Lamination

This coating makes the paper feel very smooth and expensive, while also making it much harder to tear.

Offset Printing

This method uses big metal plates to transfer ink onto paper and creates very sharp images for large orders.

Digital Printing

This works like a fast computer printer and is best for small orders that need many different bright colours.

Flexographic Printing

This process uses flexible rubber stamps and fast-drying ink, which is perfect for printing on very long paper rolls.

Screen Printing

We push thick ink through a fine mesh screen to create bold designs that feel raised on your custom packaging.

CMYK Printing

This method uses four ink colors—cyan, magenta, yellow, and black—to create almost any color you can imagine.

Pantone Printing

This system uses pre-mixed ink colors to make sure every single print looks exactly the same every time.

Metallic Ink

This special kind of ink has tiny bits of metal inside to make your printed designs look shiny.

Full-Color Printing

Using many colors at once allows you to print beautiful, bright photos that look very realistic and clear.

Embossing

This method uses a special tool to push the paper up, creating a raised design that you can easily feel.

Debossing

This process presses your design deep into the material to create a cool sunken look that feels very high class.

Foil Stamping

This process uses heat to press shiny metallic colors like gold or silver onto paper to make designs really sparkle.

Holographic Foiling

This special foil reflects many different colors like a bright rainbow when the light hits it from a certain angle.

Spot UV

This clear and shiny coating is applied only to certain parts of the page to make specific details stand out.

Matte Finish

This smooth coating provides a soft look without any shine, making the surface feel very velvety and easy to read.

Gloss Finish

This very shiny layer reflects a lot of light and makes the colors on your paper look bright and exciting.

Window Patching

We cut a hole and add clear plastic so your customers can see the product inside without opening the box.

Kraft Paper

This is a tough, brown material made from wood pulp that people often use for grocery bags and boxes

SBS Paperboard

This high-quality white board is very smooth on both sides, making it perfect for printing bright, colorful food packaging.

Coated Paper

This paper has a special clay layer that makes it feel smooth and look shiny for high-quality picture books.

Uncoated Paper

This natural-feeling paper has no extra finish, so it absorbs ink easily and is great for writing with pens.

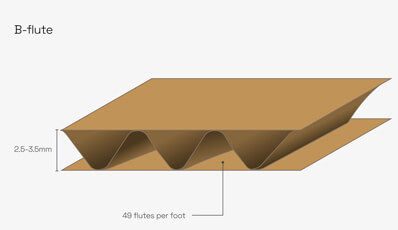

B-Flute

This strong, medium-sized cardboard resists crushing and works perfectly for mailing boxes that need to stay very safe inside.

C-Flute

As the most common shipping choice, this thick layer provides good cushioning for everyday items moved in large trucks.

F-Flute

Being the thinnest option available, this lightweight paper is used for tiny specialty boxes like jewelry or fast food.

Double Wall (BC)

By stacking two different layers together, this extra thick board creates a heavy-duty box for shipping very heavy items.

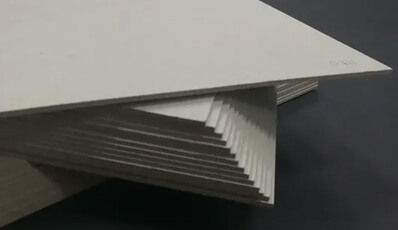

800gsm

This material is thin but strong enough to hold its shape well for small, lightweight boxes and sturdy cards.

1000gsm

A great middle-ground choice that feels very solid and provides good protection for most standard types of gift boxes.

1200gsm

This thick board feels heavy in your hand and is the most popular choice for high-quality, durable luxury packaging.

1400gsm

This is a very tough and rigid material used for larger items that need extra support to stay safe.

Samantha C.

Catering Business

Samantha C.

Catering Business

Samantha C.

Catering Business

Samantha C.

Catering Business

Samantha C.

Catering Business

We strive to accommodate your order between 8 to 10 business days, but multiple factors are involved in the process. Product line for which you need packaging

Absolutely, yes, no matter which packaging type you contact us for, you will experience earth-friendly packaging material in every purchase. We take pride in our services, and this is one of them; our consults acknowledge us for serving them sustainable options.

We offer you boxes at wholesale price with a minimum order limit of 50 boxes. Plus, design and material consultation and shipping all over the USA services automatically cut down the overall cost. You can also contact a customer representative to enjoy custom packaging at the minimum possible rate.

Absolutely, yes, no matter which packaging type you contact us for, you will experience earth-friendly packaging material in every purchase. We take pride in our services, and this is one of them; our consults acknowledge us for serving them sustainable options.

You do not have to worry about it; all popular payment methods, Visa to Master card payment, Amex to Discover, and PayPal, are acceptable.

Our team will send you a design file for final approval. You can also ask for physical sampling for better assessment. This is done to remove possible bugs in packaging design, material, and printing. After the assessment process, production has started.